Products & Services

Aquaculture Tanks

GFI Composites provides a range of aquaculture tank models designed to meet hatchery and grow-out tank requirements. Our fiberglass tanks are lightweight, durable, and rustproof, ensuring long-term reliability.

While our tank sizes vary, our standard sizes range from 36″ in diameter to 10′ in diameter, offering flexibility for different aquaculture applications.

All standard fiberglass tanks come ready to use, eliminating the hassle of liners. Unlike steel tanks, fiberglass is rustproof, and with proper maintenance, it can last indefinitely—making it a smart and sustainable choice for aquaculture operations.

Circular Storage Tanks

GFI Composites offers a variety of aquaculture tank models to suit all hatchery and grow out tank requirements. These fiberglass tanks are lightweight, durable and rustproof. Although our tank sizes vary our standard sizes range from 36″ diameter to 10’ diameter.

All of our standard fiberglass tanks are built ready to use. There is no struggling with liners, unlike steel tanks fiberglass is rustproof and if properly maintained, can last forever.

Accessories

- PVC fittings

- Covers

- Leg extensions

- External stand pipe

Rectangular Storage Tanks

GFI Composites offers a variety of aquaculture tank models to suit all hatchery and grow out tank requirements. These fiberglass tanks are lightweight, durable and rustproof.

All of our standard fiberglass tanks are built ready to use. There is no struggling with liners, unlike steel tanks fiberglass is rustproof and if properly maintained, can last forever.

Accessories

- PVC fittings

- Covers

- Leg extensions

- External stand pipe

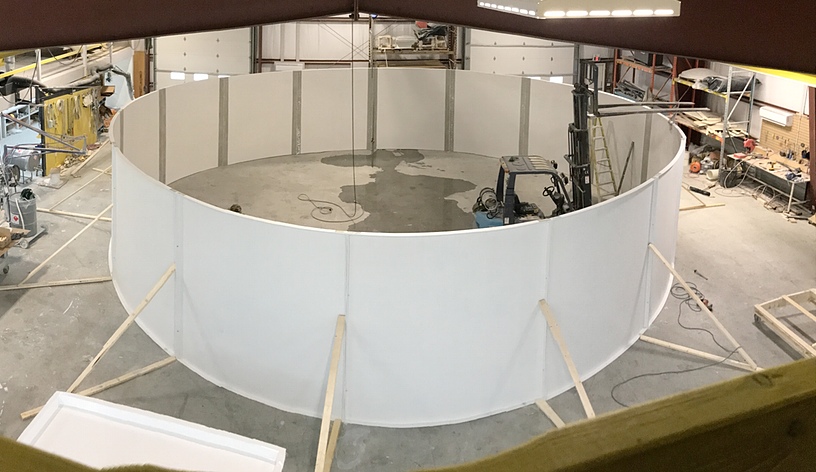

Panel Tanks

GFI Composites offers a variety of aquaculture tank models to suit all hatchery and grow out tank requirements. These fiberglass tanks are lightweight, durable and rustproof.

Panel tanks satisfy the needs of larger volume tanks upwards to 42′ in diameter along with being effectively transported and installed onsite using only three to four fiberglass technicians.

Accessories

- Support stands

- Side pods

- Sump and Stand pipe assemblies

- Fiberglass covers

- Flanged nozzles with gussets

- PVC couplings

- FRP couplings

- On-site technical support

Swirl Separator Tanks

For Aquaculture facilities we offer a full range of swirl separators sizes. The swirl separator component in re-circulation systems provide an effective first stage in the removal of solids which lightens the demand on your filtration system downstream.

We design our swirl separators with a tangential inlet and conical bottom to allow maximum efficiency of separation. Our sizes range from a capacity of 90 liters – 4,300 liters.

Tank Refinishing

GFI Composites process for resurfacing/recoloring of fiberglass tanks is a very cost effective alternative to replacement.

Many customers resurface their fiberglass tanks to change the color. However, the majority resurface because their fiberglass has lost its original finish or spider cracking has occurred. The result is the tank has become dull and difficult to keep clean.

The reason for this is that, over the years, all of the cleaning and water running over the tank has worn away the original finish and the tank has become porous. All of the dirt, grime, and hard water stains get trapped inside of the pores. This results in you having to use abrasive cleaners and a lot of scrubbing to get the tank clean. As you can imagine, this only wears away the finish further. A new fiberglass tank has colored finish or gel coat applied to it over the raw fiberglass compound when it was originally made. GFI Composites is, in effect, applying a new finish coat to your tank. The new finish coat is applied as a liquid, so the tank is non-porous when we are finished. The result is your tank will look better, last longer, and clean much easier.

Technicians are trained and certified in Fall arrest, Confined space, First Aid and Whims to ensure your job is carried out safely and with no negative impact to the environment.

Onsite Installation Services

Field fabrication and installation can be highly cost-effective and efficient. When large components need to be assembled on location, field fabrication and installation often overcome size and access problems.

GFI Composites can produce on site installation when transportation of our products is impossible due to size and available transport methods.

Our technicians are trained and certified in Fall Arrest, Confined Space, First Aid, and Whims to ensure your job is carried out safely and with no negative impact to the environment.

Industry Standards

Below are just a couple Industry Standards GFI Follows from API, ASME, ASTM, CSA and NSF:

- Currently Certified Under NSF/ANSI61 standard. For potable water tanks and vessels. We can meet requirements that potable water tanks meet NSF Standard 61, including verification that we performed leak testing before shipping the tank. GFI Composites offers NSF-listed tank designs, and our manufacturing plant is NSF-certified, which means that NSF can audit us at any time to confirm our materials and processes.

- In accordance with ASTM D4097 (Aquaculture)

- All staff are Certified Composites Technicians (CCT Program) by American Composites Manufacturers Association

- Certified & Pre-qualified by Nimbi and ISNetworld